Teasing the history of knitting from diaries, pattern books, and photographs may be difficult, but finding the history of knitting yarn can prove even more elusive. Company archives disappear into fires and floods, and often paper records are eventually simply discarded. Occasionally, however, a window onto historical yarn may open serendipitously as it did with my $5 purchase at a flea market of a booklet titled How to Use Florence Knitting Silk (Florence, Massachusetts: Nonotuck Silk Company, 1882). (In 1882, Nonotuck would have mailed me the booklet free of charge on receipt of two 3-cent stamps.) Its tattered covers hang by shreds, but inside, the dog-eared pages detail forty-seven “rules” (instructions) for fashion patterns, fancy stitches, and free knitting advice, exquisitely illustrated. Directions for creating a lampshade with 928 pieces of fringe cut from silk knitting yarn remind today’s reader of the rigors of Victorian-era chic. All patterns call for pure silk yarn.

How to Use Florence Knitting Silk piqued my curiosity about the history of silk knitting yarn in America. I began to unravel it, starting with the names Florence, Nonotuck, and Northampton, and the Corticelli brand of silk yarn.

Corticelli Purse Twist thread

Corticelli Purse Twist thread

Early Silk Production in America

Coveted for its distinctive luster and affinity for dyes, silk was treasured and held in secret in Asia for millennia before it was smuggled into Byzantium and transported along ancient trade routes into Europe in the late Middle Ages. Europeans introduced sericulture (the production of raw silk through the cultivation of silkworms) into North America as early as 1613, predicting that it would become a backbone of the colonial economy. But although English kings reportedly supplied colonists with silk cocoons and mulberry trees, urging silk production in place of tobacco, American silk entrepreneurs had little appreciation for Asians’ experience and skills in raising silkworms and reeling silk cocoons.

The story of Corticelli Silk can be traced to Samuel Whitmarsh (1801–1875) and the founding of the Northampton (Massachusetts) Silk Company in 1837. Whitmarsh built a “cocoonery” on his property, promoted raising silkworms as a cottage industry, and speculated on mulberry trees. When word spread that Whitmarsh was promoting the shrubby ‘Multicaulis’ cultivar of white mulberry (Morus alba) over all other mulberries as food for ravenous silkworms, investors poured their savings into the purchase of ‘Multicaulis’ trees, drastically inflating the market. When the economic bubble burst, in 1839, the Northampton Silk Company, along with many other American sericulture endeavors, failed.

Anecdotal reports of wealth from silk continued to drive interest, however. The Northampton Association of Education and Industry, an abolitionist organization that was part of the broader utopian movement of the nineteenth century, purchased the failed Northampton Silk Company. Although the association strove to establish a textile industry with humane working conditions for its employees, notorious difficulties in raising finicky silkworms signaled the end of sericulture in the region by 1844, and further difficulties led to the dissolution of the Northampton Association in 1846.

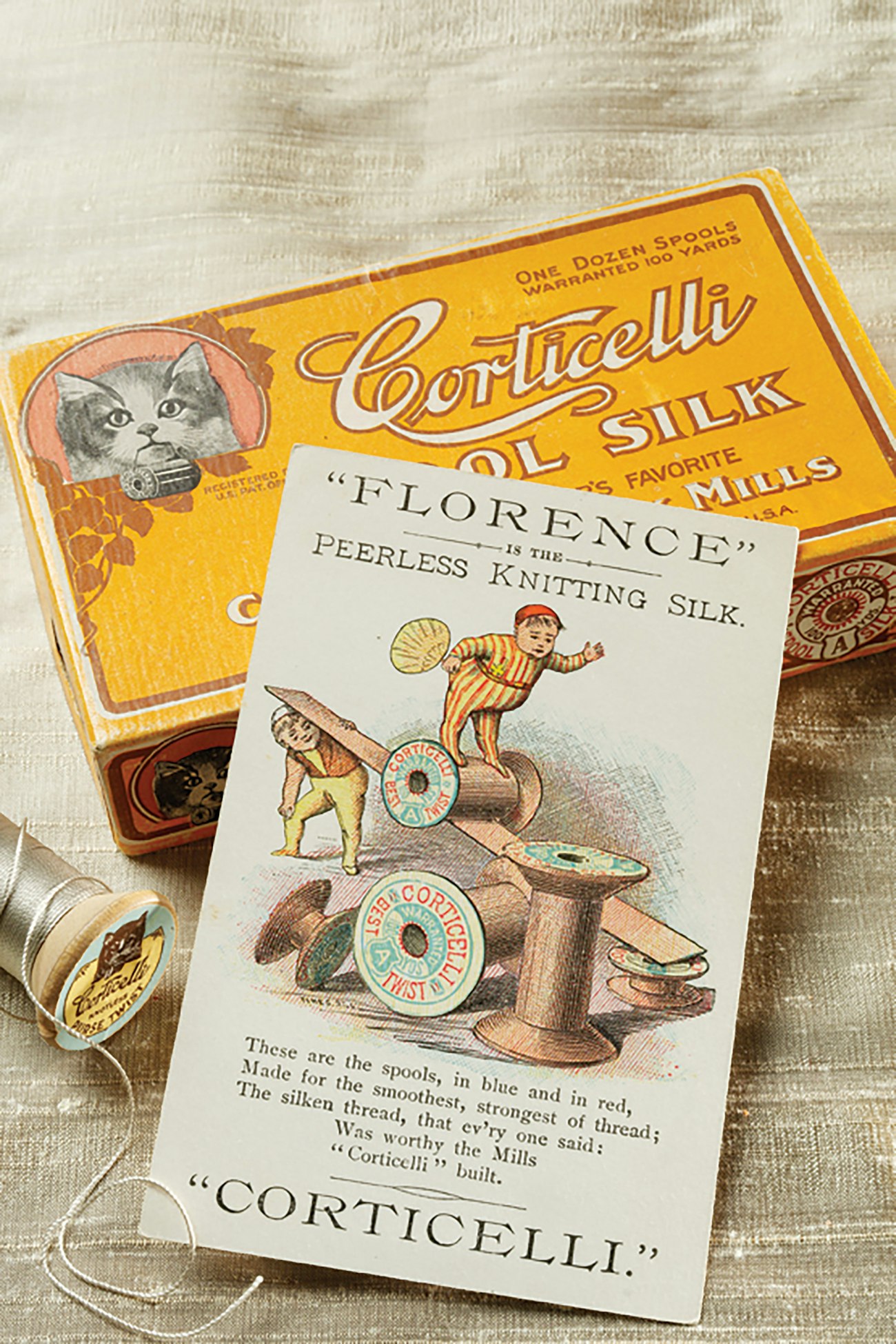

Corticelli Spool Silk thread box, Corticelli trade card, Corticelli Purse Twist thread

Corticelli Spool Silk thread box, Corticelli trade card, Corticelli Purse Twist thread

Italian Connections

Samuel Lapham Hill (1806–1882), a cofounder of the Northampton Association, purchased the silk mill, intending to import raw silk to be twisted into sewing thread for his new business, the Northampton Steam Mills. His timing was uncanny. In 1852, Hill met Isaac Singer (1811–1875), whose development of a home sewing machine design had been impeded only by the lack of sewing thread that did not tangle in the machines. Hill had the answer with a three-strand silk sewing thread spun using recently improved machinery. Smoother than either two- or four-ply thread, Hill’s “machine-twist” thread resisted tangling in sewing machines. Singer told Hill that he would buy all the thread that Hill’s company could produce. The resulting windfall for Northampton led to the city’s renaming the mill district Florence in reference to the major silk-producing city in Italy, and the Northampton Steam Mills reorganized in 1855 as the Nonotuck Silk Company, named for an American Indian tribe that had once occupied the area.

A remarkable businessman, Hill built the Nonotuck Silk Company into arguably the largest silk thread manufacturer in the world. He added lines of spun silk yarn and mercerized cotton thread for knitting, crochet, tatting, and embroidery. He capitalized further on the Italian connection by naming lines of thread or yarn Bartolini and Corticelli. Consumers gravitated to the new, Italian-sounding brands. Corticelli became so well known that in 1922 the Nonotuck Silk Company became the Corticelli Silk Company.

Raw Silk from Japan

Hill readily acknowledged that raising silkworms was better done in Japan, the source of most of Corticelli’s imported raw silk (the only sericulture that Corticelli Silk Mills practiced was raising silkworms and cocoons for educational boxes and charts). In a “little textbook” called Silk: Its Origin, Culture, and Manufacture, Corticelli described the labor-intensive process needed to raise “Corticelli Silkworms” in Japan.

According to the book, the silkworm egg “resembles a turnip seed” from which a tiny black worm with sixteen legs emerges; thousands of worms munching mulberry leaves make a “noise like falling rain.” After shedding its skin four times, the worm (actually a caterpillar), now 3 inches (7.6 cm) long, spins its cocoon. Emerging at the rate of 9 to 12 inches (22.9 to 30.5 cm) a minute from the spinneret, an opening near the mouth, two strands of liquid silk harden on contact with air to form a single thread bound together with sericin.

The caterpillar metamorphoses into a moth within the cocoon, which, left to its own devices, would eventually burst out, breaking the silk threads into countless short pieces. So that the silk may be reeled as continuous filament fiber, cocoons must first be steam-heated to kill the moth. According to the Corticelli book, it took experienced Japanese workers to sort cocoons by color and texture, remove outer loose silk, soften the gluelike sericin, then brush, clean, and unwind each cocoon until only one thread showed. Threads from several cocoons were gathered together and repeatedly doubled and twisted—a procedure requiring great skill—into hanks of raw silk for export to Corticelli.

Spool of Corticelli’s Florence Knitting and Crochet silk thread

Spool of Corticelli’s Florence Knitting and Crochet silk thread

America’s Silk Road

Growing prosperity in America had created a nearly insatiable demand for silk products, especially clothing, but raw silk had to be transported halfway around the world to supply the 1,000 pounds (454 kg) of raw silk that Corticelli claimed that it manufactured into silk thread each day. American imports of raw silk increased from 1 million pounds (454 mt) in 1874 to 26 million pounds (11,793 mt) in 1914 and 51 million pounds (23,133 mt) by 1934.

To meet the increased demand for silk in America, a new “silk road” emerged to transport raw silk from Japan to America. High prices for imported raw silk justified the expense of overland transport versus the longer, slower, cheaper sea route through the Panama Canal. Not only did faster transport lessen the chance of theft of the valuable cargo (only gold and silver bullion were more highly valued) or damage to it by heat and moisture, but the market price for raw silk could fluctuate by the minute, costing manufacturers losses in the thousands of dollars while the silk was en route.

Still, the first part of the journey had to be by sea. American freighters equipped with rooms designed to protect silk from moisture damage crossed the Pacific Ocean in eight to ten days. On arrival in Seattle, Vancouver (British Columbia), or San Francisco, silk cargo was loaded in a matter of hours onto special “silk trains” headed for East Coast distribution centers. From 1910 through the late 1930s, hundreds of silk trains crossed the continent. People would gather along the routes to watch as they sped across the North American prairie, each with a steam engine pulling at least four baggage cars loaded with silk, plus a coach for crew and guards. The typical coast-to-coast trip took from seventy to eighty hours.

Selling Corticelli Silk

Corticelli Silk Mills achieved fame with first-prize awards at industrial fairs and competitions. Their published pattern books were helpful and progressive: How to Use Florence Knitting Silk contains tables with calculations for various sizes of stockings knitted using different yarn weights, a chart for a thumb gore, explanation of knitting abbreviations, and even a reprinted Scientific American article extolling the virtues of Corticelli silk manufacturing. Hyperbole was not spared, as in this introduction to Corticelli Lessons in Crochet Book No. 5 (1917):

The wonderful demand that we are having for Corticelli instruction books in the art of lace making cannot be construed as anything else but a great public endorsement of these works. It is really not surprising when one considers the originality, variety and merit of Corticelli designs, the clear and beautiful manner in which they are illustrated and the explicit instructions given for their execution.

Corticelli advertisements claimed that perfection was the company’s only acceptable product, as its slogan, “Simply Another Name for Perfection” attests. The company’s advertising triumph, however, was the Corticelli Kitten. Exceptionally popular toward the close of the nineteenth century, “kitten ads” in general were used to sell all manner of products from cigars, stove polish, and railway travel to stockings, rubber heels, and silk knitting yarn.

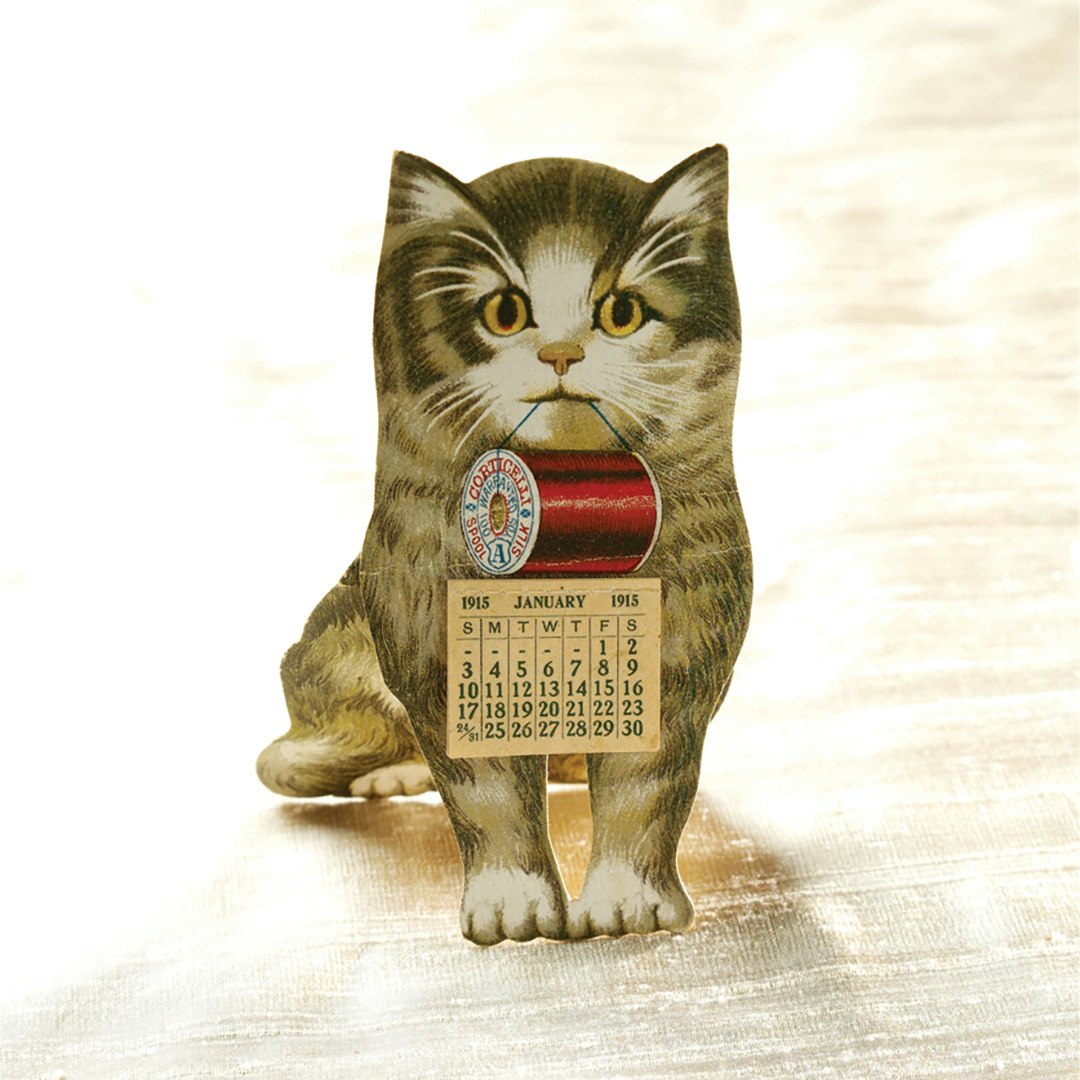

The frolicsome, fluffy Corticelli Kitten, introduced about 1900, kept the Corticelli brand in plain sight on stores’ display cabinets and eye-catching signage, and infiltrated homes across America with countless giveaways. It appeared on cat-shaped calendars, trade cards, postcards, labels, and pattern booklets, and stamped into the wood on the ends of thread spools. Advertisements in The Delineator, McCall’s, Harper’s Bazaar, and Ladies’ Home Journal showed the kitten tugging or playing with silk thread; the copy proclaimed, “Too Strong to Break—Does not Knot.” In 1911, Corticelli offered prints for sale of a painting of the kitten by Ben Austrian (1870–1921), and Corticelli Kittens appeared in New York’s Times Square entangling silk thread in their paws on one of the nation’s first electric, animated billboards. The back of a Corticelli postcard claims that the sign measured 100 feet (30.5 m) long by 35 feet (10.7 m) high and boasted nearly 3,300 electric lights.

Corticelli Kitten 1915 calendar

Corticelli Kitten 1915 calendar

Decline and Demise

Corticelli had expanded rapidly, but the company was plagued with problems common to the silk industry in particular and to textile mills in general: complex industrial machinery, management and training issues, strikes, growing challenges with silk supplies and prices, outdated financial practices, overproduction by competing companies, and high labor costs compared with those in Europe and Asia. In 1913, for example, American workers earned an average daily wage of $1.50 to $3 for eight to ten hours of work while Japanese made a mere 15 to 20 cents for ten to fourteen hours.

Following World War I (1914–1918), a further challenge arose with the advent of “artificial silk” (rayon or viscose), including standardized yarns quickly developed for needlework. During the war, a blockade of German dyes and other chemicals had compelled the United States to train its own chemists and produce its own chemicals. Spurred by postwar concerns that a similar blockade of Japanese silk could occur if relations with Japan deteriorated, America supported rayon production, which grew accordingly from an estimated 1.5 million pounds (680 mt) in 1913 to 35 million pounds (15,876 mt) by 1935. The cost of rayon remained less than half that of silk even when the price of silk plummeted from $18 per pound ($39.60 per kg) in 1920 to $3 ($6.60) in 1930 and $1.30 ($2.86) in 1934.

The fashion for simpler dresses with shorter skirts during the 1920s had decreased the demand for silk fabric and silk sewing thread, and American women were willing to settle for less than the best in ready-to-wear clothing. In the manufacture of airplane wings, metal skins began to replace coverings of treated (“doped”) cotton fabric sewn with silk thread. The stock market crash in 1929 and the ensuing Great Depression greatly reduced the demand for luxuries such as silk thread and silk knitting yarn. In 1930, Corticelli discontinued mill production in Florence, and in 1932 it merged with Belding-Heminway; the resulting Belding Corticelli company closed operations in Northampton the same year.

Although traces of the Corticelli name in Florence persist only in street names and mills converted to apartments or offices, the knitting legacy of Corticelli lives on in our enjoyment of luxurious silk and silk-blend knitting yarns—and in the survival of vintage Corticelli patterns for knitting silk. And, having learned of them, who could fail to appreciate the romance of the silk trains or the appeal of the Corticelli Kitten?

Resources

- Chittick, James. Silk Manufacturing and Its Problems. 1913. Reprint, Charleston, South Carolina: BiblioBazaar, 2009.

- Feitelson, Ann, and Peter Weis. “The Silk Industry of Florence, Massachusetts.” PieceWork, January/February 1999.

- Field, Jacqueline, Marjorie Senechal, and Madelyn Shaw. American Silk 1830–1930: Entrepreneurs and Artifacts. Lubbock, Texas: Texas Tech University Press, 2007.

- Iseminger, Gordon L. “Silk Trains on the Great Northern Railway.” Minnesota History Magazine, Spring 1994.

- Muncaster, Alice L., and Ellen Yanow. The Cat Made Me Buy It: A Collection of Cats Who Sold Yesterday’s Products. New York: Crown, 1984.

- “Raw Silk Culture and the Manufacture of Sewing Silk.” Scientific American 47(4), July 22, 1882.

- “Silk in Northampton.” Northampton Silk Project, Smith College, Northampton, Massachusetts. Members of the Smith College community, local historians, and artists explored and documented the silk industry in and around Northampton; www.smith.edu/hsc/silk.

- Silk: Its Origin, Culture, and Manufacture. Florence, Massachusetts: Nonotuck Silk Company, 1895, 1902. Reprint, Florence, Massachusetts: The Corticelli Silk Mills, 1911. Out of print (available online at www.archive.org/details/silkitsorigincul00nono).

Fascinated by silk and want to learn more? Check out the November/December 2010 issue of PieceWork.

Also, remember that if you are an active subscriber to PieceWork magazine, you have unlimited access to previous issues, including November/December 2010. See our help center for the step-by-step process on how to access them.

Susan Strawn is professor emerita at Dominican University in River Forest, Illinois. She researches and writes about stories held in textiles and is a PieceWork contributing editor.

Originally published December 2, 2020; updated April 10, 2023.